Don't be tied to the calf shed every day! A robotic feeder will give you your time back.

The CalfExpert will feed your calves, giving you back control of your own time, significantly reducing manual labour, reducing the stress of calf rearing, and helping grow better herd replacements. The CalfExpert is so easy to operate and sets new benchmarks in automated feeding with many functions to make your work easier.

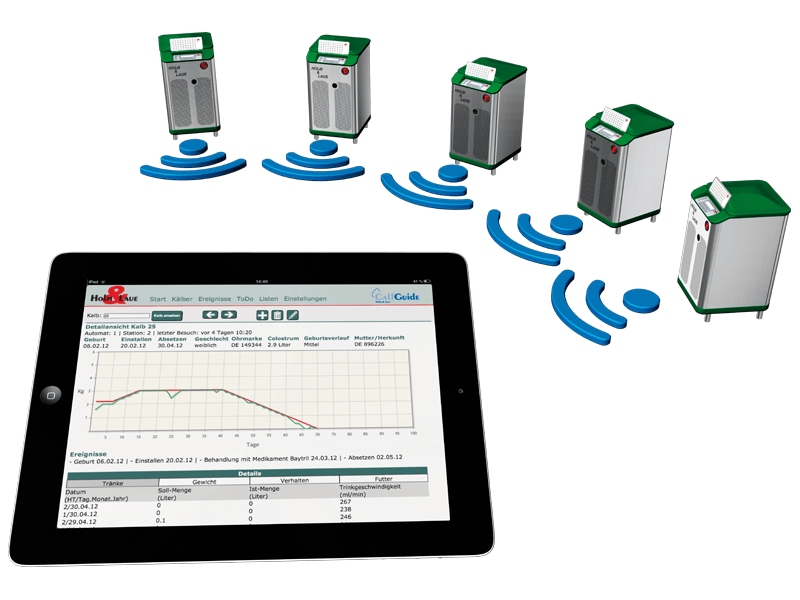

Monitor the health of your calves with information and control at your fingertips on mobile, tablet, or at the control unit. The CalfExpert also monitors levels of CMRs, whole milk, additives, and cleaning chemicals and reminds you to refill when levels are low with automated txts.

Adapting every feed to individual calf needs when feeding multiple calves can be an enormous challenge, particularly in manual feeding scenarios. But the CalfExpert does it all effortlessly, providing the opportunity to feed whole milk, growth powders, milk replacers, or combinations of all of the above. Medicines and electrolytes can be added to the feed programs of any sick calves.

The Flexitime program guarantees that feeding is spread throughout the day, reducing waiting times for high numbers of stock.

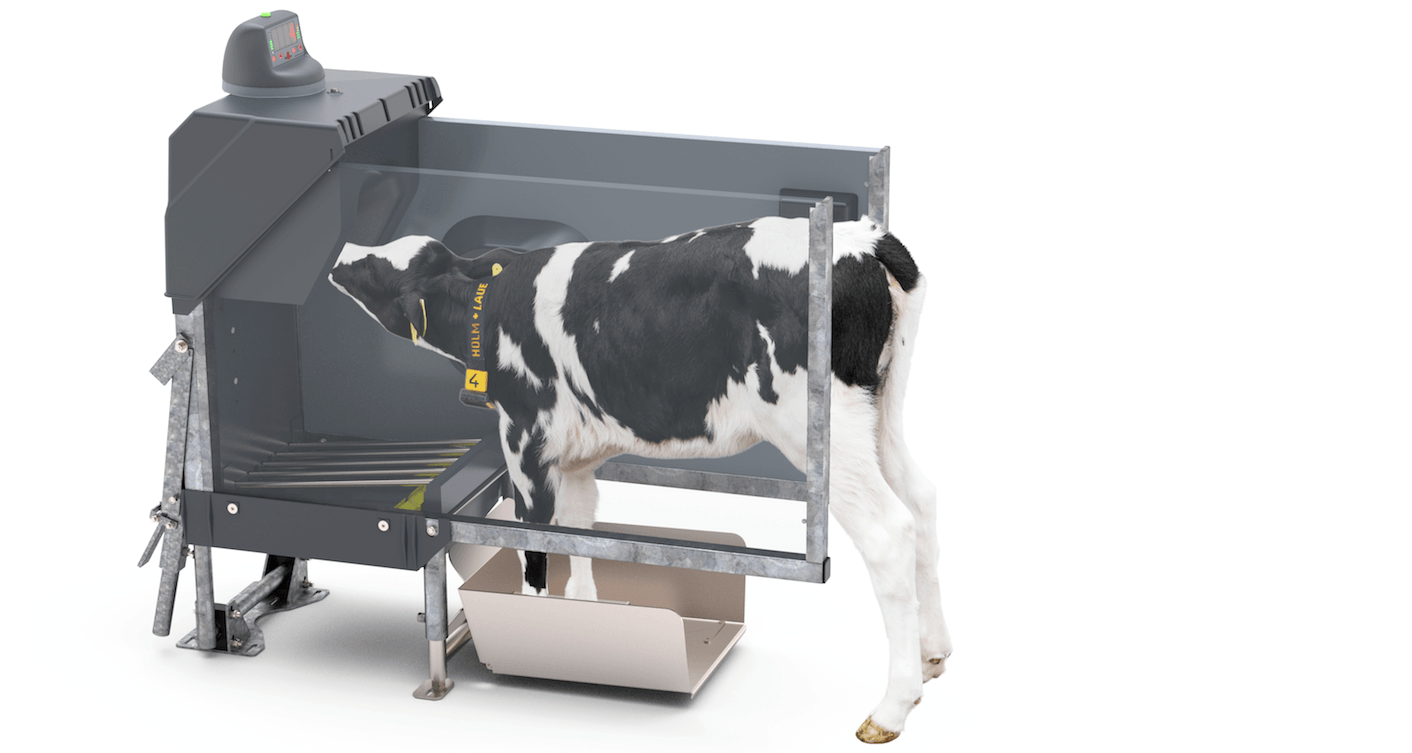

Younger and weaker calves have all the time they need to drink their full rations without having to compete, while stronger calves can’t steal rations, ensuring all calves have a positive nurturing experience. You should notice a more even line.

When it’s time to wean, the milk reduction process provides a gentle and natural transition from a milk diet to forage feed.

The Hygenic feed preparation and individual mixing guarantee the optimum feeding of your calves, producing healthy, strong, and even lines of stock every time they drink. Hygiene is a critical factor in calf rearing.

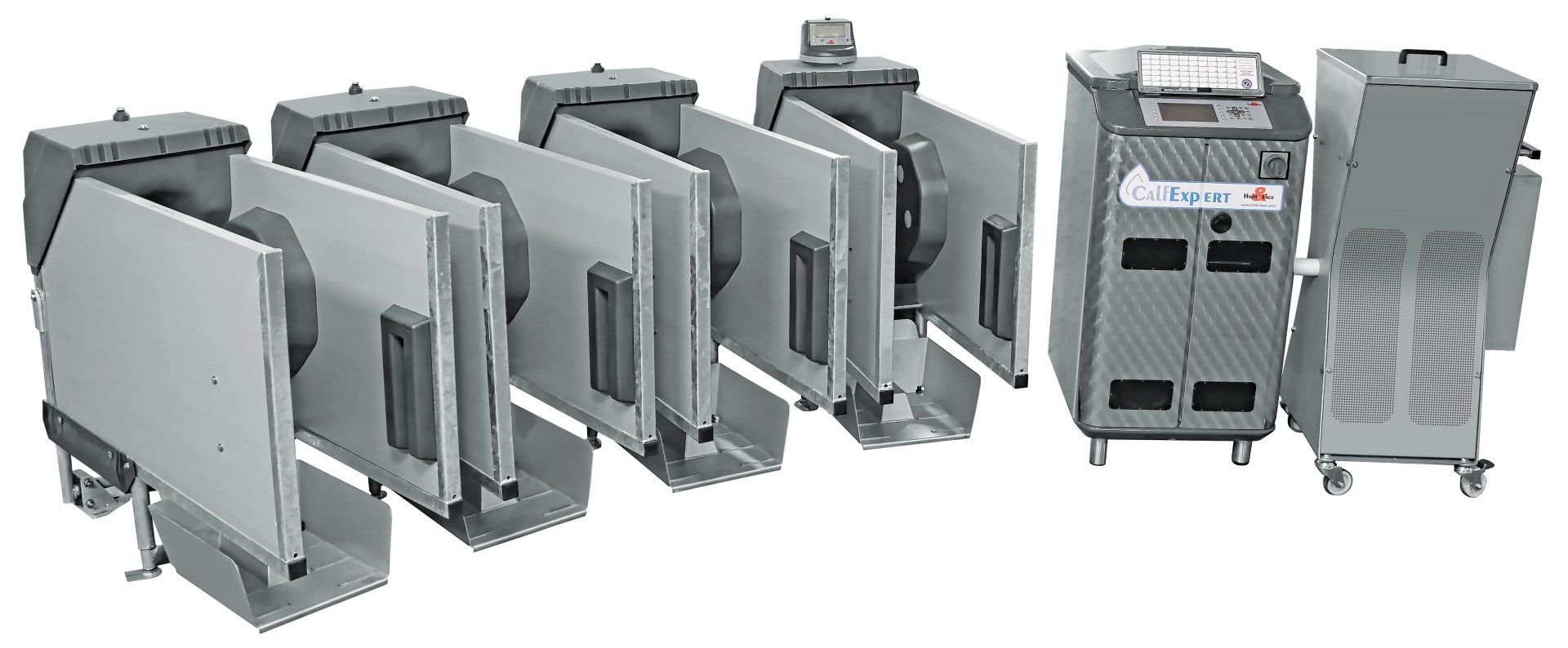

The HygieneStation ensures the cleanliness of the feeding area, and ensures each calf always has a clean teat. It accommodates two separate cleaning agents and a fly screen comes as standard.

The CalfExpert freshly mixes feed for every calf. Faster mixing technology ensures that the milk is available at the HygieneStation - in only three seconds from completion. If there is any residual milk in the bowl, it is kept warm, but after any sustained pause, the station rinses the entire milk line from the base unit through to the teat, in addition to the complete milk system, which self-cleans several times a day.

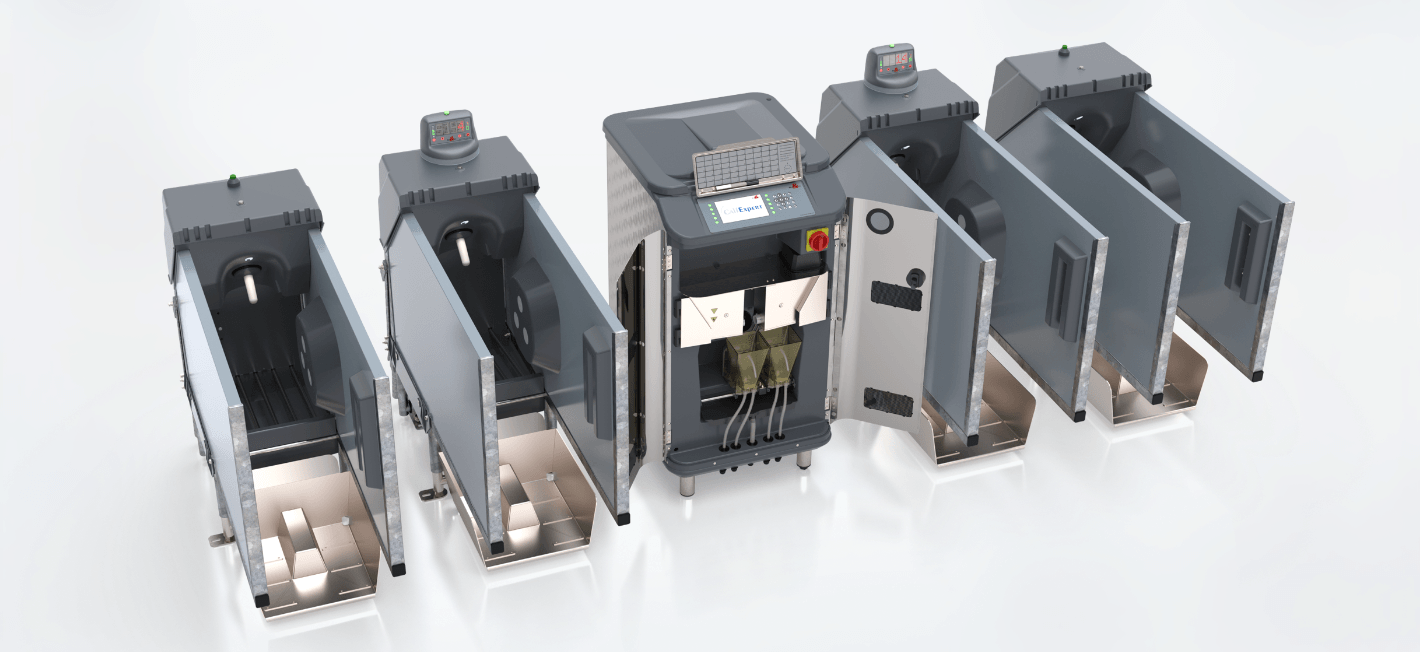

The CalfExpert provides proven pre-set feeding programs for different scenarios. Flexible feeding means that a wide range of milk additives or powders can be prepared lump-free. To avoid splashes, the CalfExpert’s PowerMixers begin mixing slowly, before transitioning to a more intense stirring pattern.

To prevent powders from separating, the PowerMixer will slowly continue to stir the ration no matter how long the calf takes to feed. When the weather is colder, the heater in the PowerMixer always ensures the mix is kept at a constant temperature and an anti-freeze program activates automatically when there is a risk of frost, so it’s ready to work whatever the weather.

From the southern-most parts of Southland to the far North, smart operators are trading their sore backs, missed breakfasts, and heavy lifting, for happier families and healthier calves.

Options and Features

Basic Version

- Two PowerMixers with SoftStart logic and heaters.

- Milk freshly prepared on an individual basis for each animal.

- CalfExpert feeding software with integrated operating instructions and help functions.

- 7' display with SrnartKeys.

- Eight feeding curves pre-set (incl. metabolic feeding curve) with adaptation possibilities for individual animals.

- Rinsing of mixing tank and suction line.

- Two detergent pumps for the automatic cleaning of all milk-carrying components with automatic empty message.

- Wash temperature up to 65°C.

- Easy-to-clean surfaces made of stainless steel or plastic.

- Whole milk system for variable dispensing of whole milk percentages from 35 - 7 00%, equipped with an effective heat exchanger spiral and automatic cleaning as standard.FEEDERS

- Powder store for 50kg CMR with only 712cm filling height.

- Powerful powder-conveying auger suitable for various CMRs.

- Early empty warning for milk replacer powder.

- Automatic registration of new calves.

- Flextime feeding capabilities, to avoid stressful regular feeding hours.

- QuickChange logic for faster credit changeover between the calves.

- Can feed up to 150 calves (with four HygieneStations).

- Anti-freeze program that is activated automatically.

- Fly sheild.

- Wi-Fi as standard in the calf feeder.

- Liquid doser for liquid feed additives and medicines.

- Important information can be received on mobile devices.

- Push messages for warnings (e.g. CMR empty soon).

Technical Specifications

Technical specifications - CalfExpert*

Power supply and heating performance - 400V16A(6kW) or 230 V 16 A (3 kW)

Capacity with four feeder stalls - up to 150 calves (under certain conditions)

Identification system - Multireader HDX and FDX

Storage tank for milk replacer powder - 90L/ 50kg

Powder filling height - 1.12m

Heater Capacity - 12L Dimensions of CalfExpert (w x d x h) - 0.6 x 0.7 x 1.21m

Space requirement for Calf Expert - 1 x 1 m

Technical specifications - HygieneStation*

Power supply {VDC) - 24V

Water inlet - 1/2”

Optional teat and grid rinsing permissible water pressure - 1.4 • 8.2 bar

Weight of fully equipped HygieneStation approx. - 50kg

Permanent sound pressure level - <70d8

Dimensions of HygieneStation - (w x d x h) 0.47 X 1.31 X 1.08m

Space requirement for HygieneStation - 0.50 X 2.3m

Technical specifications subject to change

Options

HygieneStation

- Up to four feeding stalls per CalfExpert.

- Pump as an automatic and manual training tool for calves, as it delivers milk diet to the teat.

- Anti-pirate valve to prevent stealing of milk.

- Distance of up to 7m between feeder and stall possible.

- Animal recognition via H&L collars or ISO-compliant ear tag identification (half-and full-duplex mode).

- Can be tilted away for mucking out.

- LED teat lighting.

- Saliva bowl.

- Teat is rinsed by water following every visit.

HygieneStation display

- Display of animal number and alarm status.

- Indication of alarm and credit calves.

- Release of an extra mix.

Animal weighing scales

- Forefoot WeighScale in the feeder stall for individual calf management and individualised weaning function.

CalfGuide (available 2022)

- Management software with own server.

- Bidirectional control of the Calf Expert.

- Locally functioning variant (without internet), integrated Cloud connection.

QuadroFlex

- Simultaneous feeding of four calves, with flexible adaptation to individual calf needs.

Powder additive doser

- Up to two dosers for powdered additives and medicines, with dietetic program to prevent diarrhoea.

Liquid additive doser

- One further liquid doser for liquid additives and medicines.

Hopper Extension

- Stacking frame for another 25kg CMR (filling height 138 cm).

Additional powder hopper

- Additional stand-alone powder hopper capable of holding up to 40kg of powder.

Alarm lights

- Indicate operating status of machine from outside calf shed.